French design

From Paris to Fukui

At the very beginning, during the drawing stage, we like to retreat to the city of Fukui, nestled between the mountains and the Sea of Japan, close to our factory.

We bring with us notebooks filled with sketches of shapes, colors, and impressions from our time between Paris and Tokyo.

In this calm place, where the spirit of the pioneering artisans of Japanese eyewear still lives, our new creations take shape.

Japanese quality

"Japanese craftsmanship subjected to the most rigorous quality control"

In the city of Sabaé, three hours from Tokyo on the shores of the Sea of Japan, eyewear manufacturing has earned the most prestigious reputation since the early 20th century, from handmade prototypes to assembly, polishing, and quality control.

Each prototype is entirely handcrafted to validate the feasibility of the technical design before it goes into production.

Here, the acetate surface of the Anna model is polished manually using a cotton wheel. With the help of a polishing compound, the artisan gently buffs the acetate surface of the frame to achieve a mirror finish. For each stage of this process, we use a specific compound (abrasive compound for deburring, coarse sanding compound for smoothing, and polishing compound for shining).

Final stage of production: each frame (here, the Anna model) undergoes the most rigorous quality control.

It is also in Sabaé, at the company Tega Seiko, that the metal components forming the frame structure and hinges of our glasses are produced. When it comes to assessing the durability of a frame, the hinges play a central role.

Innovation

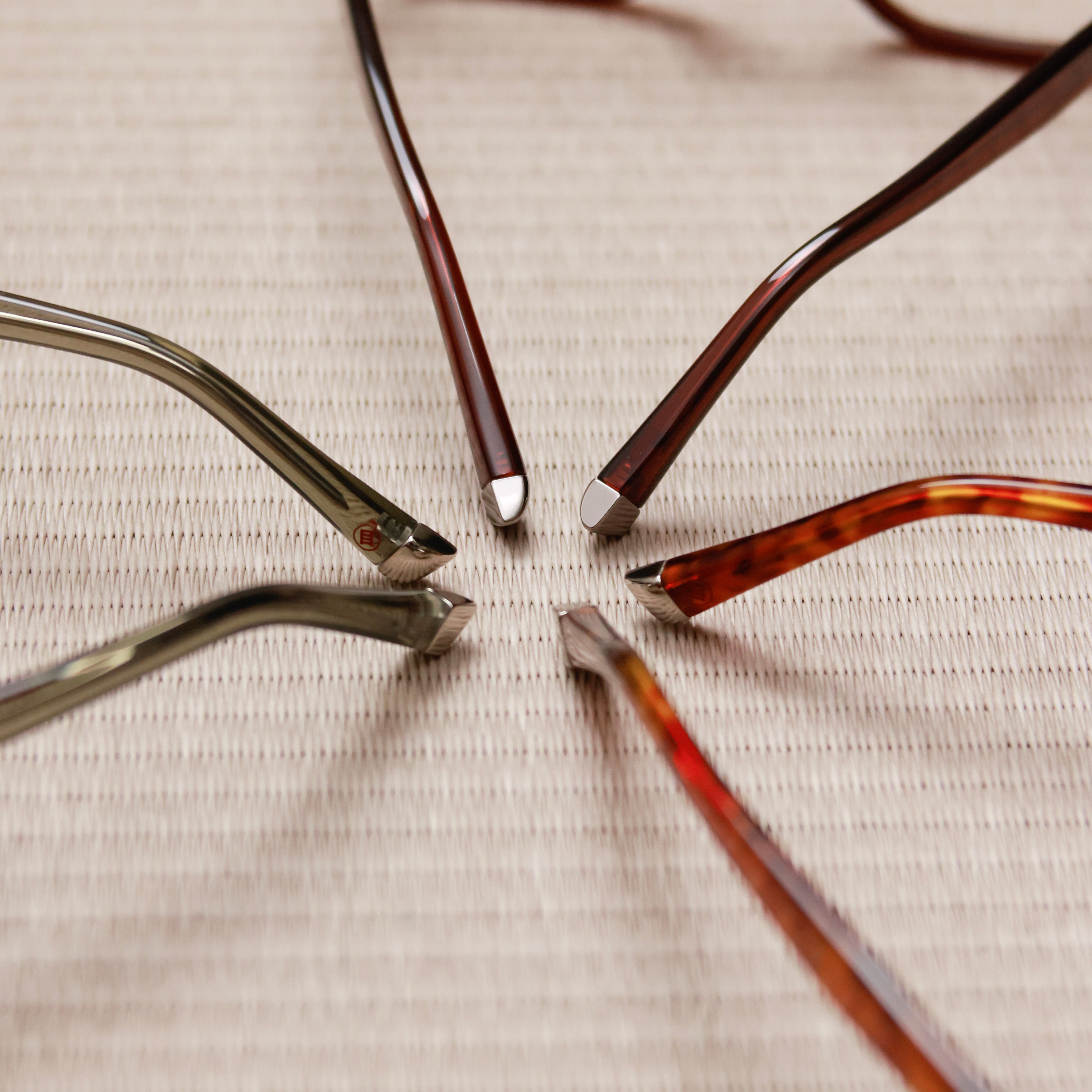

Titanium temples’ tips

The titanium tips, inserted at the end of the temples (THEO and ANNA models), add a slight weight (1,58 grams) to shift the center of gravity backward. Instead of being located at the front of the frame, near the hinge as is usually the case, it is now positioned roughly at the first third of the temple, providing a feeling of lightness at the front for optimal comfort.